Occurred on a virtual trip inside Airstream’s Basecamp production center, where every Basecamp 16, Basecamp 20, and REI Co-op Scandal Sheet Basecamp Travel Trailer is handcrafted to offer adventure-ready experiences for tourists who Live Riveted ® Join us as we check out how we construct these rugged and ingenious trailers– from their simple starts on the chassis to the last touches that make them all set for the open roadway.

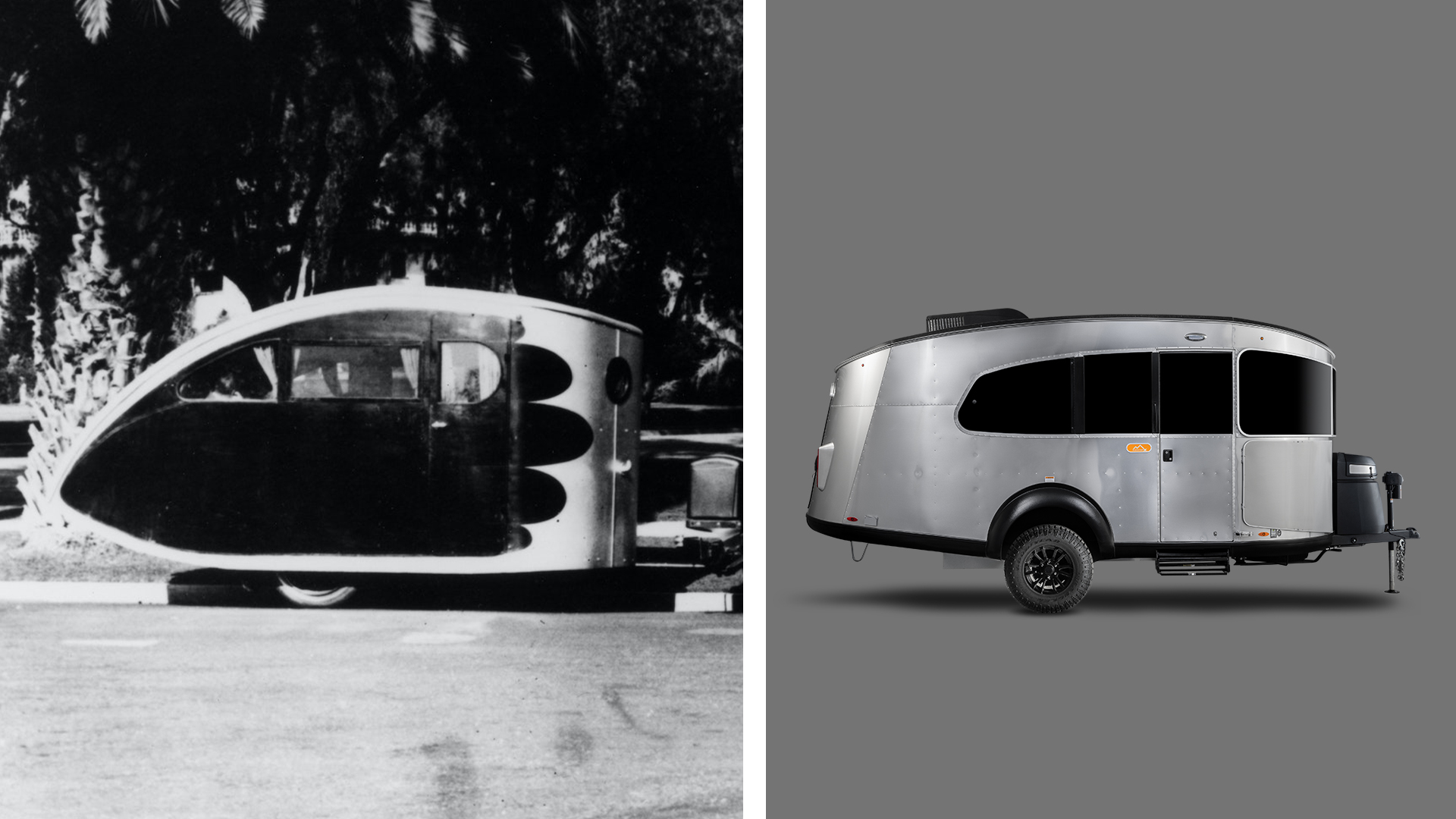

Airstream’s Basecamp design line has actually been a preferred amongst lovers for many years, and it continues to mesmerize with its mix of workmanship and style. Influenced by among Airstream creator Wally Byam’s initial travel trailers, the Torpedo, the Basecamp was initially produced for the 2007 design year. In 2017 it was upgraded with more facilities and enhancements to improve its off-grid abilities and guarantee a comfy travel experience. Today, we make all Basecamp 16, Basecamp 20, and REI Co-op Scandal Sheet Basecamp Travel Trailers in this center.

Now, you can step inside Airstream’s Basecamp Production Center on a brand-new video trip. Get an up-close take a look at each of the construct stations and see as we make Basecamp Travel Trailers from the wheels up. Then, arrange an in-person trip of our Basecamp plant and see it on your own.

See our virtual trip of Airstream’s Basecamp Production Center and arrange an in-person trip today to see it on your own.

Arrange a Trip

A Very Popular Design Line Constructed on an Iconic Structure

Airstream’s Basecamp design line has actually been a preferred amongst lovers for many years, and it continues to mesmerize with its mix of workmanship and style. Influenced by among Airstream creator Wally Byam’s initial travel trailers, the Torpedo, the Basecamp was initially produced for the 2007 design year. In 2017 it was upgraded with more facilities and enhancements to improve its off-grid abilities and guarantee a comfy travel experience.

The Basecamp Production Center

Found in a 70,000-square-foot plant in Jackson Center, Ohio, the Basecamp production center is nearby to our Touring Coach producing center. Initially built in 1978, this center ended up being the home of the Basecamp assembly line after a considerable growth in 2017. Here, the spirit of experience comes to life as competent artisans handcraft each Basecamp trailer with utmost accuracy and attention to information.

Structure the Basecamp Structure

The production procedure starts in the chassis construct location, with the arrival of the ladder frame chassis. Rubber torsion axles, independent wheel suspension, and wheels are diligently set up, together with the essential circuitry and pipes. The floor covering, made from composite product for enhanced sturdiness and water resistance, is thoroughly set out to finish the structure.

Crafting the Basecamp Shell

Neighboring in the shell construct station, the compact yet robust riveted aluminum superstructure of the Basecamp takes shape. Utilizing made steel frame jigs, craftspeople put together the shell elements. Aluminum frame pieces, pre-formed down the street in Airstream’s Travel Trailer production center, are accompanied durable dollar rivets to develop a resilient and renowned structure. Thermal barrier bonding tape is contributed to improve insulation, while the front breathtaking and side windows are set up to assist flood the interior with natural light.

Attention to Information

As the Basecamp advances along the assembly line, the exterior and interior elements are included phases. From electrical circuitry and pipes to doors, pipes lines, and LP elements, every information is thoroughly thought about. The roof elements, consisting of cooling systems, photovoltaic panels, and venting, are set up and sealed. Undercarriage body covers and fender flares are contributed to offer the Basecamp its rugged look.

The Basecamp Water Inspect

Like every Airstream item, we put the Basecamp through a 25-30 minute water check. Throughout this procedure, an Airstream partner inside the Basecamp shell searches for any leakages. On the uncommon celebration that a leakage is discovered, it’s fixed and returned for another water check. Just as soon as we are particular that the shell is water tight does the Basecamp make its method to the last goal where furnishings, devices, seating, and more are set up.

Putting Up Insulation and Aluminum Skins

Upon returning from water check, interior insulation is contributed to the walls and ceiling. The next action includes shaping and setting up aluminum interior skins, which develop a riveted shell within a shell and offer the Basecamp its signature glossy interior. These aluminum skins are produced down the roadway at Airstream’s Travel Trailer center.

After the setup of aluminum skins, the interior trim and storage bars are thoroughly set up. Lighting components are placed on the ceiling, and fuse panels, heating unit, and battery box are set out, installed, and protected. The interior circuitry is routed through pre-cut extrusions in the aluminum skins, and the photovoltaic panel battery charger and converter are likewise set up.

Basecamp’s Wet Bath, Cabinets, and Seating

Once the water pump, hot water heater, pipes lines, and drains pipes are set up, the damp bath is installed and set up, and all pipes connections are protected. A pressure test is carried out to guarantee there are no leakages, and as soon as validated, the shower surround and cut are set up.

The preliminary pieces of kitchen cabinetry for Basecamp are prepared by Airstream’s wood store group situated in the neighboring Class B touring coach center. Utilizing a CNC router, the kitchen cabinetry panels are specifically cut to preserve quality and attain exact tolerances. The element pieces are then revived over to the Basecamp center where competent partners in the woodshop construct each cabinet by hand, making sure the exact same level of workmanship discovered in all Airstream items. When constructed, the galley, dinette, and bench pieces are then positioned in their designated areas and protected.

Window Treatments and Home Appliances

Window treatments, consisting of blackout drapes, are produced down the roadway in the sewing department at Airstream’s Travel Trailer center. When finished, the window treatments are provided to the Basecamp plant for setup. Home appliances such as range tops and microwaves are likewise set up. In addition, the shower doors are fitted and adapted to guarantee an appropriate fit and surface.

Quality Assurance and Last Touches

After the significant elements have actually been set up, the Airstream group concentrates on the smaller sized information that contribute to the general beauty and performance of the Basecamp. Mirrors, cushions, drapes, trim, and pedestals for the tables are thoroughly set up at this phase. Lastly, the gas tank cover is set up as the last production product on the outside.

Before the Basecamp is all set for shipping, a detailed last walk-through is carried out. The system goes through an extensive cleansing, followed by comprehensive system tests and visual assessments. Inspectors test devices, examine the LP gas system for pressure and fill the drain system to guarantee no leakages. Usually, each trailer goes through 1,500 assessment points. If any product stops working to satisfy requirements, it is immediately sent out for repair work. When all assessments are finished, the exterior and interior get a last cleansing.

Airstream uses 21st-century innovation, consisting of internal software application advancement and digital tools, to preserve long lasting quality. Inspectors bring tablets with comprehensive lists customized to each design and its functions. These tablets are linked to the quality department and transport department, making sure real-time information transmission. Just systems that attain a passing grade are launched for delivering to licensed Airstream dealerships.

Starting Basecamp Experiences

After effectively passing assessment, the Airstream Basecamp is all set to leave Jackson Center and make its method to licensed Airstream dealerships, where excited clients wait for the chance to start their trip experiences. From the riveted aluminum shell and long lasting chassis elements to the hand-built kitchen cabinetry and precise quality evaluation, Basecamp is an essential part of our renowned travel trailer lineup. From the preliminary style motivated by Wally Byam’s vision to the workmanship and attention to information, Basecamp embodies the spirit of experience.

Prepared to take your own Basecamp experience? Download a Basecamp pamphlet and find your nearby dealership to see our most daring travel trai ler yourself.

Download Your Sales Brochure

Find Your Nearby Dealership